Can you hear the „E“?

How can the power of e-transport be enhanced?

High payloads, formidable torque and rugged engineering hold the key to a breakthrough for electric transport. With a view to adopting electromobility for heavy goods service, Hellman and Paul Nutzfahrzeuge are putting their trust in BPW.

|

AN INDUSTRY HEAVYWEIGHT THAT TAKES SUSTAINABILITY SERIOUSLY.

The family enterprise Hellmann Worldwide Logistics (13,000 employees and 255 branches in 56 countries, annual sales of around 3.2 billion euros) is taking a keen interest in the future of ‘green logistics’. Dr. Dustin Schöder, Manager In-house Consulting & CIP Surface and Contract Logistics at Hellmann, has been evaluating the deployment of electric commercial vehicles in the consumer goods distribution segment from a technical and economic perspective. Outlining his preliminary conclusion, he says, “There’s no justification for the hype concerning operating radius. The critical factor is actually payload, because transport operators carry more than just parcels.” For this reason Dr. Schöder and his team are now conducting a six-month trial involving general goods distribution with an electric vehicle. The trial spans three regions in the north and west of Germany and involves highly diverse operating environments. Mathias Magnor, Chief Operating Officer Road & Rail at Hellmann Worldwide Logistics, comments, “Given the threat of diesel vehicle bans in city centres, this field trial will enable us to gather valuable data and experience.” The test vehicle is powered by BPW – to be more precise, the driving force for the truck, which has been converted especially for Hellmann and has a maximum permissible gross weight of 7.5 tonnes, is delivered by BPW’s electric axle drive eTransport. At present, electric commercial vans have a plated weight of just 2 to 3.5 tonnes.

The platform for the test vehicle is provided by the Mercedes-Benz Vario – the classic heavy commercial van that remains popular in the industry in view of its rugged construction. Around 20,000 Vario vans are still in service throughout Germany, most of them with specially modified or converted bodies to suit the needs of local authorities, road maintenance crews, the police or fire services. To avoid the embarrassment of municipal authorities issuing diesel bans contrary to their own interests, the BPW drive axle has been earmarked to give these costly custom vehicles a new lease of life with zero emissions. Paul Nutzfahrzeuge of Vilshofen in Bavaria, which ranks among the European leaders in special-purpose vehicle construction, is currently developing a standard conversion programme for an electric future. It will take only about two weeks to exchange the diesel engine for an electric axle. The batteries and power and control electronics – developed by BPW – do not increase the vehicle’s weight because the original transmission, drive shaft and exhaust gas system are to be removed as well. In consequence, the payload will not be reduced at all and additional installation space will be gained.

|

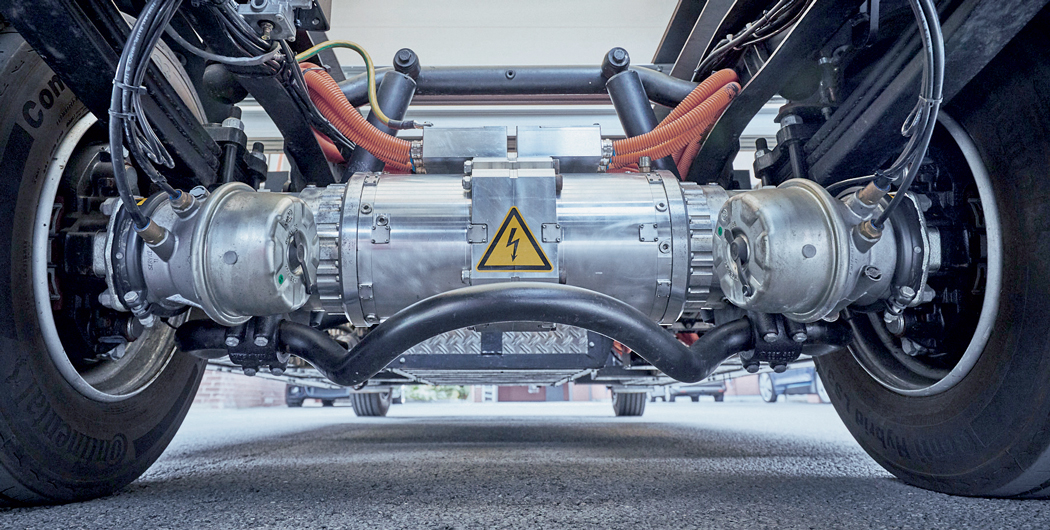

“As a rule, urban transport vehicles cover relatively short distances during the day, and spend the night in a depot,” explains Hans Werner Kopplow, BPW’s electric transport development chief. “Electric drives are a perfect match for their operating profile. BPW’s drive technology, which develops a massive 3,250 Nm of torque per wheel, readily takes care of large payloads, heavy bodies and steep inclines, all of which are typical of public sector operations.”

ELECTROMOBILITY

The electric drive axle is extraordinarily powerful and exceptionally light. It tips the scales at less than the original axle of the Vario van, while the unsprung weight remains practically unchanged.

“The future of inner-city transport belongs to the electric axle drive because it drastically reduces both local harmful emissions and noise. It is also very powerful and compact. We are already developing an electric drive

with a torque of 11,000 Newton metres per wheel for vehicles up to 26 tonnes gross vehicle weight.”

|