BORN DIGITAL

The way in which trailer running gear at BPW is configured, manufactured, shipped and maintained is undergoing radical change. The components are conceived and endowed with DNA online. Running gear weight is reduced and vehicle manufacturing is simplified, and access to intelligent services is ensured throughout the product lifetime.

Welcome to the Matrix

The axle beam with the ID number 0552079120 is digitally aware. It knows every detail of its own technical and physical attributes – from its weight to its compatibility with air bags, trailing arms, brake systems, hangers, ride heights and other running gear components.

CONFIGURING BPW RUNNING GEAR IS BECOMING

AN ACT OF DIGITAL CREATION.

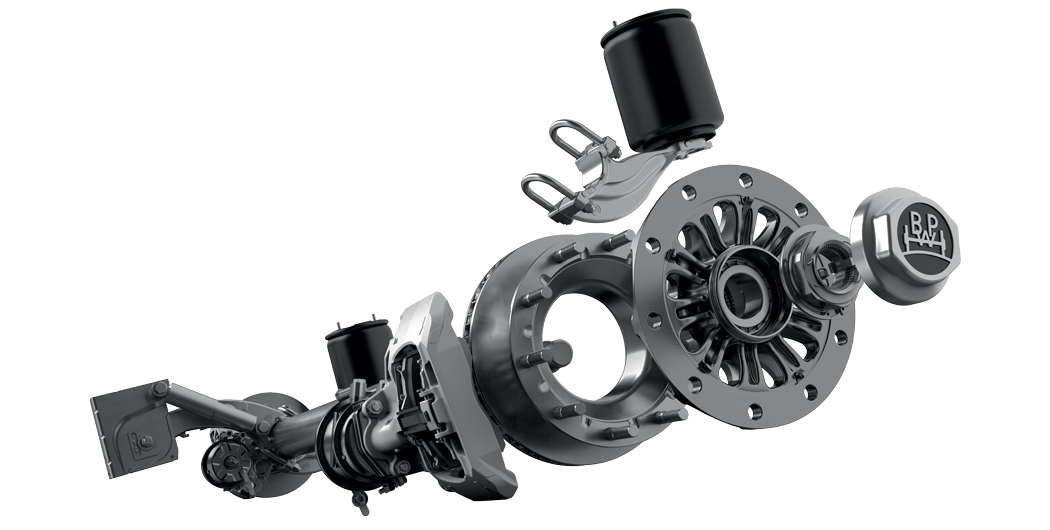

Every single component of BPW running gear carries with it precise digital information about its own identity and compatibility with all conceivable applications and vehicle specifications. The number of possible permutations runs into trillions. The network of correlations created in this way forms the basis of an entirely new component matrix that enables vehicle manufacturers to configure running gear for a specific application online. This approach automatically avoids compatibility conflicts and, click by click, produces a three-dimensional image before the designer’s eyes. Once the configuration is complete, he can retrieve a CAD model in order to design a corresponding body and exchange ordering data with the relevant purchaser – without any paper trail. With the click of a mouse, the order confirmation creates a digital genetic code that remains with the running gear throughout its service life. It orchestrates and enhances the efficiency of ordering, manufacturing and shipping the running gear, as well as its subsequent maintenance and aftermarket support.

But not every innovation associated with the new generation of ECO Air running gear is digital. BPW has filed a patent application for a laser welding technique, which for the first time allows ultralight round axle beams to be combined with BPW’s clamped axle mounting. The running gear’s reduced weight further extends the range of configuration options. And modular architecture with standardised, intelligent components enables vehicle manufacturers to purchase BPW running gear in kit form and install the components in the desired configuration on their own premises. This approach minimises lead times and maximises flexibility by allowing manufacturers to produce a wider range of running gear in a short time – and embrace late-stage customisation.